Priorities laid bare for high-quality FDI

Priorities laid bare for high-quality FDI

Ssupporting industries have emerged as a vital link in the country’s efforts to attract high-quality foreign direct investment and enhance the competitiveness of its manufacturing base.

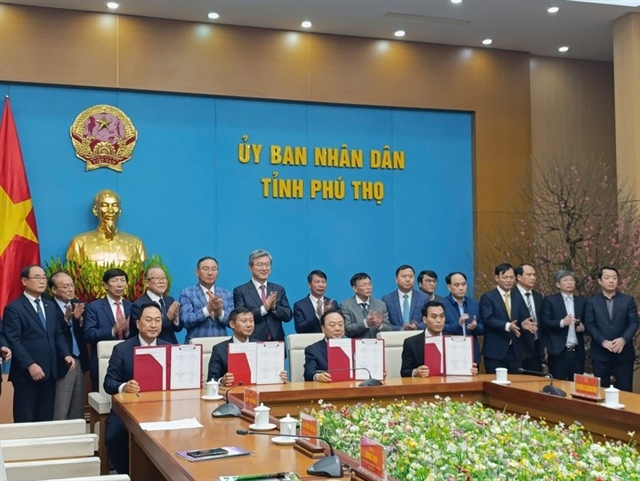

At a policy dialogue held nearly two weeks ago in Hanoi on how foreign direct investment (FDI) contributes to Vietnam’s industrialisation, experts noted that such investment has played a transformative role in building a robust industrial sector, facilitating urban infrastructure growth, and advancing workforce quality.

According to a report released at the event, FDI has helped shift Vietnam’s economic structure towards industry and services. Between 2011 and 2024, the share of these sectors in GDP rose from 73.5 to 79.9 per cent. The country also saw a major leap in its industrial competitiveness index, from rank 95 in 1990 to 31 in the 2019-2022 period, driven by strong manufacturing capacity and exports.

Despite accounting for only 8 per cent of enterprises in the manufacturing and processing sector, businesses involved in FDI contribute 56 per cent of total capital investment, generate 62 per cent of revenue, and employ nearly 60 per cent of the labour force.

“FDI is the backbone of Vietnam’s current key industries. It has powered Vietnam’s rise as a global manufacturing and export hub, especially in electronics,” said Dr. Bui Quy Thuan of the Vietnam Industrial Park Finance Association. He added that since 2010, FDI has increasingly shifted from labour-intensive sectors like textiles and footwear to high-tech industries, with electronics growing from 4.1 per cent to 17.8 per cent of the FDI share.

However, lack of labour, infrastructure bottlenecks, and uneven policy enforcement continue to limit the potential of FDI to contribute more broadly and deeply. A key concern is the over-reliance on low-skilled labour - 72.1 per cent of related workers have no formal training - and the slow, unstable rise in productivity.

Truong Van Cam, vice chairman of the Vietnam Textile and Apparel Association, emphasised the need for detailed statistics on FDI inflows by sector and their socioeconomic impact. He pointed out that the textile and garment industry has attracted over $30 billion in FDI, far surpassing other sectors in export value, investment, and employment.

“Yet foreign investors largely bypass fabric production and dyeing, preferring assembly due to local environmental regulations and unclear policies,” Cam said. “Localities often reject textile dyeing projects out of pollution concerns. We must attract FDI in stages where domestic firms are weak, such as fabric production - China’s strength.”

Cam also advocated for clear and consistent policies to bridge the gap between local and foreign businesses. For instance, allowing foreign-invested enterprises (FIEs) to participate more fully in industry associations could foster mutual understanding and technology sharing. In his view, FIEs have also been a valuable training ground for Vietnamese professionals, many of whom later launched successful, competitive local firms.

While sectors like garment manufacturing no longer need FDI, Cam noted that Vietnamese companies still struggle to compete for labour. In provinces like Thai Binh, FIEs offer monthly salaries up to approximately $600, compared to around $470 at domestic firms. This underscores the need for alternative strategies, including improved workforce training.

Moreover, there are mounting concerns over FIEs reporting losses despite continuous expansion. Their contribution to the state budget remains disproportionately low compared to their scale of operations.

To maximise FDI’s contribution to industrialisation, the experts proposed a strategic policy overhaul: shifting from broad-based incentives to a selective, performance-based approach. New incentive frameworks should be tied to research and development, tech transfer, local content ratios, and investments in high-quality workforce development.

Equally important is strengthening domestic enterprises and developing genuine supporting industries. Vietnam should implement a national supplier development programme, build robust platforms for FDI-local firm connections, and tailor support packages by industry and business size. Human capital development must be prioritised through real collaboration among the state, academia, and FIEs, the event heard.

In addition, a coordinated national mechanism should be created to delineate central and local roles in FDI attraction. Local authorities need better project appraisal capabilities, while administrative reforms and transparency are essential to ensure a fair and competitive business environment.

As of now, Vietnam has attracted over 43,300 valid foreign-invested projects with a total registered capital of $517.14 billion. Actualised capital stands at nearly $331.46 billion, representing around 64.6 per cent of total commitments.

One concern for Vietnam’s FDI attraction is an over-reliance on workers with no formal training, photo: Klingai |

Pham Hai Phong, chief administrative officer Vietnam Association for Supporting Industries

We have initially established an ecosystem for supporting industries, comprising experienced manufacturers capable of supplying components and parts to FIEs in Vietnam. These companies primarily engage in component manufacturing and product assembly – stages that add relatively low value in the global value chain. We are now making efforts to move to upstream activities such as design, branding, and research and development.

In Vietnam’s manufacturing supply chain, approximately 70 per cent of raw materials are imported. Around 200-300 firms operate as Tier 1 component manufacturers, supplying higher-value sub-assemblies and specialised parts. Nearly 2,200 firms fall into Tier 2, focusing on intermediate machined parts and sub-assemblies of low to medium complexity. An estimated 5,000-10,000 firms are Tier 3 suppliers, producing stamped, pressed, and rolled metal products, as well as basic machined components.

Our network covers five core sectors: mechanical engineering, electronics and electricals, plastics and rubber, materials, and automation systems. Automation is expected to become an additional focus soon, helping to complete the domestic supporting industry supply chain and meet the growing demands of foreign-invested manufacturers.

Current investment and development trends are increasingly focused on assembly, product design, and advanced materials. We are confident that Vietnamese supporting industry enterprises are capable of meeting most of the requirements set by upstream manufacturers in the supply chain. In addition to attracting investors, we are also working to develop several commercial products based on existing manufacturing and assembly activities for foreign brands already operating in Vietnam.

Given the US imposition of reciprocal tariffs on Vietnamese goods, although the tariff rates are relatively modest compared to other countries in the region, they still create pressure on Vietnamese supporting industry enterprises. This situation necessitates enhanced origin traceability, strengthened internal capacity, proactive negotiation and dialogue to increase imports from the US, and further diversification of export markets, including the EU, Japan, South Korea, ASEAN, and other emerging economies.

Nguyen Anh Tuan, chairman Vietnam Association of Foreign-Invested Enterprises

A more in-depth assessment is needed regarding the development and contribution of FDI since 2019. This would reflect the strong growth of inflows in recent years, despite difficult circumstances and a global decline in such flows. In fact, FDI inflows into Vietnam have either remained robust or continued to increase. Vietnam currently ranks third among ASEAN countries in attracting FDI.

Vietnam still depends on such investment, but this dependence is gradually decreasing. Vietnam’s planned development of the private economic sector has recognised the achievements and role of the domestic private sector. However, the success, growth, and technological autonomy of local businesses today in some industries are contributed by the support and cooperation with FIEs that began decades ago or in some cases, continues today.

For example, in telecommunications, the cooperation a few decades ago with Australia’s largest telecoms company Telstra was the foundation for the development of the telecommunications industry today. In the automotive industry, the long-standing presence of Toyota, Honda, and Ford has been transferred technology and developed supporting industries, paving the way for the success of VinFast. In the oil and gas sector, joint ventures with foreign partners in exploration have allowed Vietnam to master some stages of production like refining and petrochemicals.

Masaru Onaga, CEO, Onaga Vietnam Co., Ltd.

Onaga is contributing to the advancement of Vietnam’s aviation industry through the production of aircraft components, the development of supply chains in Vietnam, supporting local enterprises in improving their quality management systems, assisting Japanese companies in expanding operations in Vietnam, and cooperating with Japanese firms in the joint manufacturing of aircraft parts.

However, we have encountered several challenges during the process of building the supply chain. For supporting companies, we visit each one individually to help them obtain AS9100 certification, but frequent schedule changes have posed difficulties.

One major issue lies in the need to spend significant time explaining why the requirements of AS9100 are necessary. We require an English-to-Vietnamese translation of the AS9100 standard, specifically highlighting the additional requirements compared to ISO9001. Therefore, we hope that Vietnamese companies can share in the cost of obtaining AS9100 certification and provide a Vietnamese translation of the standard.

The Vietnamese government should standardise the format of each required submission document and provide examples of how to complete them. There should be a common understanding between the person in charge and their supervisors, checklists should be created for verifying submitted documents. The overall process should be simplified so that Japanese companies can enter the Vietnamese market without needing to rely on consulting firms.

- 08:00 19/08/2025