Bridging the tech-led links in investment

Bridging the tech-led links in investment

Although Vietnam has been improving its business and investment environment significantly throughout the last four decades, the cooperation between domestic and foreign-invested companies could be much improved, especially when it comes to the technology and quality gap between what the former side currently offers and what the latter demands.

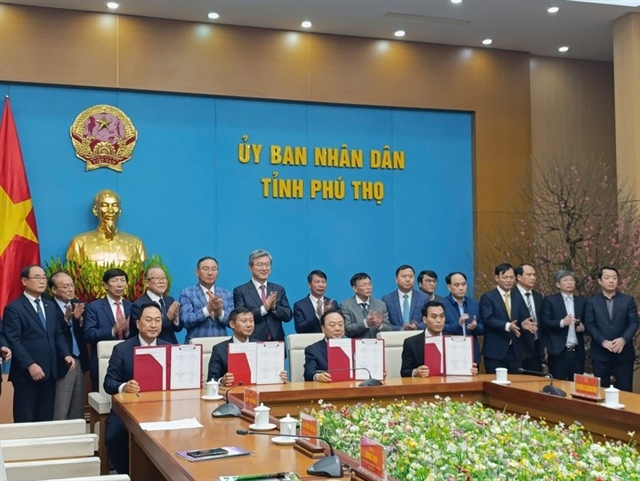

Domestic suppliers still have a lot of potentials in linking with foreign-invested partners, photo Photo: Le Toan

|

Currently, a good 50 Vietnamese enterprises have become top suppliers for Samsung Vietnam. The South Korean conglomerate has given the necessary support to help these companies improve their manufacturing processes and better meet global supply chain standards – but becoming one of its regular suppliers is no mean feat.

Hoang Minh Tri, general director of 4P – the first domestic company to supply electronic circuit boards to LG Electronics Vietnam – said that supplying Samsung with these products is especially difficult as the company has strict standards for quality, expertise, technical precision, and high professionalism.

4P was thus forced to reform its business according to Samsung’s requirements, accepting technical standards and working conditions in the company, even for employees on how to use sterilised rooms and equipment properly. According to Samsung, these practices relate to the scientific stages in the production process and, if carried out correctly, can prevent risks as well as quality issues.

Vietnamese businesses must thus meet these criteria set by Samsung to become one of its suppliers. Kim Kyung Tae, senior expert at Samsung Vietnam, noticed that performance and management are the limitations of these companies.

Passing all those evaluation criteria, Kim said, is “a real challenge”. Vietnamese businesses must prepare thoroughly in order to meet these criteria. And yet, Samsung also has other evaluation indicators related to the environment, the vendor’s financial potential, and its documentation practices.

Samsung is close to its goal of increasing its localisation rate to 57 per cent, as well as fulfilling its commitment to the government to promote the development of supporting industries. But the addition of Vietnamese enterprises in the supply chain also helps Samsung reduce the cost of importing components, improve competitiveness, and increase profitability.

Samsung remains the largest foreign investor in Vietnam with the registered investment capital of $17.5 billion. In 2020, the total export turnover of Samsung Vietnam reached about $57 billion, a relatively positive result in the context of the complicated pandemic and its negative impacts on the global economy.

According to a VIR source, in Samsung’s list of vendors, about 80 per cent are large-scale foreign-invested enterprises (FIE) from South Korea, China, and Japan. Among them are Samsung Electro-Mechanics, Samsung SDI Vietnam, and MCNEX Vina, which produces camera modules. Other suppliers include Power Logics Vina which delivers battery protection boards, CammSys Vietnam which provides camera modules, Goertek Vina that delivers headsets and mics, and more – and none of them are Vietnamese companies.

Weak links

Data from the Ministry of Planning and Investment (MPI) shows that after nearly 35 years of national renovation, Vietnam’s private economy has continuously maintained a fairly good growth rate, accounting for 43 per cent of GDP and attracting about 85 per cent of the workforce. However, the development of the private economy’s quality is an issue that Minister of Planning and Investment Nguyen Chi Dung described as concerning at a meeting on March 12.

Minister Dung said that the links between Vietnamese businesses remain lax and do not focus on mutual development. As such, domestic enterprises have not been focusing on improving links and competitiveness to participate in the regional and global value chains.

“Currently, only about 21 per cent of small- and medium-sized enterprises participate in parts of the global value chain, and 14 per cent are successful in associating with foreign partners, while the number of FIEs in Vietnam is very high,” the minister said.

According to him, the productivity and growth rate of the private sector is low and limited. Statistics show that the average labour productivity of private companies makes up only about 34 per cent of the labour productivity of state-owned enterprises and about 69 per cent of foreign-invested enterprises. This low productivity is related to the fact that most enterprises are micro- or small-sized ones, accounting for about 98 per cent of all enterprises.

Capacities in science and technology also remain limited, with some being outright backward, the MPI minister pointed out. “Enterprises have not invested in the application and development of science and technology, especially core and pioneering technologies,” Minister Dung said.

Currently, only 10 per cent of businesses have registered patents within three consecutive years. Meanwhile, enterprises’ investment in technology and innovation only accounts for about 0.3 per cent of their revenue, much lower than in countries like India (5 per cent) and South Korea (10 per cent).

The shortcomings of private companies, according to Minister Dung, are partly due to the state management of the economy. The system of mechanisms and policies on private economic development still has many shortcomings and lacks synchronisation. Although the investment environment has been improved, it remains still limited, with access to opportunities and development resources not being equal, which incurs many intermediate and informal costs.

Weak links have been prevalent in the economy for many years. The provincial competitiveness index of the Vietnam Chamber of Commerce and Industry (VCCI) showed that the proportion of domestic private enterprises participating in the supply of goods and services in the production chains of FIEs has been limited for many consecutive years. By 2017, only about 10 per cent of domestic businesses provide input goods to FIEs operating in Vietnam.

Links are also very weak from the perspective of FIEs. According to the VCCI’s data, only about 27 per cent of their input value is purchased in Vietnam, but a significant proportion is supplied by other FIEs. Especially, those operating in high-tech manufacturing tend to import goods from their own countries and use fewer local suppliers.

Establishing connections

Vietnam is changing its strategy of attracting foreign direct investment (FDI), focusing on quality projects coming from former and current big investors, emerging and growth-leading economies – an opportunity to promote links between FIEs and domestic enterprises, following the Politburo’s Resolution No.50-NQ/TW on the orientation to perfect institutions and policies to improve the quality and efficiency of foreign investment cooperation by 2030.

The increased realised capital in the first two months of 2021 was a positive sign and was estimated at $2.5 billion, up 2 per cent over the same period in 2020. Many major FIEs are expanding investment in Vietnam this year.

For example, LG Display increased its capital by $750 million, adjusting the total sum for the fourth time since beginning to invest in Vietnam. Up to now, the total investment capital of LG Display poured into the northern city of Haiphong has reached $3.25 billion. As planned, after receiving its investment registration certificate, the company is now quickly building and installing necessary facility extensions that are expected to start production by May.

Meanwhile, after its previous investment project to manufacture tablets and laptops in the northern province of Bac Giang, Foxconn has just had a business trip in the north-central province of Thanh Hoa to explore new opportunities in the production of electronics.

Such endeavours are currently increasing and contributing to the connection between FIEs and domestic firms, while the government is working on improving the legal framework. Analysts said in addition to improving quality of labour and narrowing the gap in the technology levels of FIEs and domestic ones, it is also necessary to pay attention to geographical factors.

The establishment of separate industrial and export processing zones can help improve the efficiency of operations and exports but has also limited positive spill-over effects on domestic private companies.

Vietnam has partaken in negotiating and signing 17 free trade agreements, 14 of which have been signed and put into effect. Kyle F. Kelhofer, senior country director for Vietnam, Laos, and Cambodia at the International Finance Corporation, said that an adjustment to investment attraction is necessary for Vietnam, and that this should focus more on strengthening the links between Vietnamese firms and FIEs to create shared interests, which will contribute to Vietnam’s overall goal of deeply international integration.