Ice-Loft targets development of a smart cold chain model

Ice-Loft targets development of a smart cold chain model

The ambition of Belgian cold chain enterprise Ice-Loft to build a smart cold logistics system in Vietnam would complete logistics services and redirect the nation’s main fruit exports to Europe and the Middle East, which are showing great demand for tropical fruit varieties.

Ice-Loft targets development of a smart cold chain model

|

Currently, Vietnam is one of the five largest fruit and vegetable exporters in the world thanks to strong growth in markets like China, Japan, the United States, Russia, Indonesia, Taiwan, and South Korea.

It is also believed that newly-implemented trade agreements will bolster Vietnam’s cold supply chain – the main transportation means for agri-goods. However, these agreements are not a magic bullet and a world-leading cold chain logistics sector cannot emerge overnight as the sector is currently fragmented, with the majority of players being small- and medium-sized service providers operating locally without the capacity to cover the food supply chain from end to end.

A report by market research firm FiinPro highlights the cold chain as one of the most promising logistics segments for growth in Vietnam due to soaring demand from the retail and food and beverage sectors, creating opportunities for both local and international companies.

The findings point to rapidly rising demand for cold transportation as investment costs in this area are relatively lower than cold storage while profit margins are higher. As a result, cold storage companies are expanding their business to also include transportation services.

Developments in the industry could also reduce food loss after harvest. According to a CEL Consulting report from 2018, 25 per cent of produce was lost on average before it actually reached processing plants or distribution centres.

Understanding the great potentials of Vietnamese tropical fruit exports while being aware of the limitations in the current logistics services for exporting fruit, Ice-Loft – a Belgian enterprise that provides diverse intelligent cold chain logistics solutions for the storage of frozen and chilled fruit and vegetables, container yard storage, and transportation – aims to contribute to redirecting the main fruit export routes of Vietnam. It aims to do this by promoting a better cold logistics system between the Mekong Delta and Europe for the export of not only fruits but also other potential refrigerated products.

|

Testing new models

Ice-Loft plans to develop a smart cold chain of three component platforms, namely local smart cold cabin, provincial departure platforms, and a large central platform.

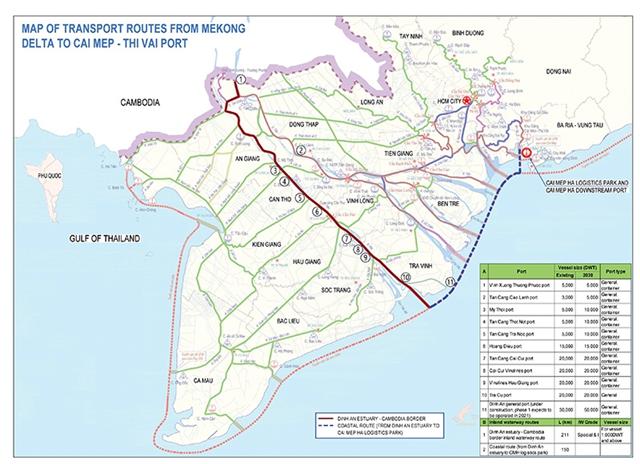

The model aims to facilitate seamless transportation of fruit and vegetables from the production point (local smart cold cabins) through the developed inland waterway network of the Mekong Delta (provincial departure platforms) to the transshipment point at Cai Mep Ha Port of South Vietnam (the central platform), which is capable of handling 20,000 twenty-foot equivalent unit (TEU) container vessels, making it an ideal international logistics hub.

In July, Ice-Loft launched its Local Smart Cold Cabin Demonstration project to improve the cold logistics of fruits and vegetables in the southern province of Tra Vinh. Under the project, Ice-Loft is building and testing the first Local Smart Cold Cabin model near pre-selected fruit farms of the province, with support from the Ministry of Agriculture and Rural Development.

On October 12, Green Startup Foundation co-operated with Tra Vinh People’s Committee to organise the groundbreaking ceremony of the Smart Cold Cabin Demonstration project located in Cang Long district. The Interministerial Advisory Committee is the sponsor. Ice-Loft is the developer of the project. Entire materials and machinery are imported from Belgium. Local Smart Cold Cabins use the Internet of Things (IoT) technology called Smart Thermo Controller to maintain the quality of the harvested fruit in the required standard environment throughout international shipment.

The cabins are installed with two types of sensors, alpha and beta. Beta sensors register information for each box and container stored at the cabin, including product type, quality, weight, and product origin. This data will be used to set the right humidity and temperature that will be maintained in the cabin while it is transported inside reefer containers, monitored by alpha sensors. Alpha sensors enable the operator to monitor the preservation remotely. The IoT side of things is operated in partnership with Belgian IoT company Lemon Digital BVBA. According to the plan, Ice-Loft will erect Local Smart Cold Cabins near harvest areas where farmers can store harvested fruit until they are picked up with reefer containers to be brought to provincial logistics centres. There, fruit from different local smart cold cabins will be gathered and transferred to the large central platform.

“At our demonstration project in Tra Vinh, fruits are preserved in the local smart cold cabin and then transferred to reefer containers and shipped to local supermarkets as the departure platform and the central platform have not been constructed yet,” said Marc Van Bouwel, managing director of Ice-Loft.

Improving competitiveness

Ice-Loft’s designs include a system of departure platforms, or provincial logistics centres located in key provinces along the Hau River such as Dong Thap, Can Tho, Tra Vinh, Hau Giang, and Soc Trang.

These will serve as transshipment areas for fruit and vegetables on their way to Cai Mep port. Ice-Loft has yet to determine the exact area needed for the provincial logistic centres, but anticipates each cold storage area these departure platforms at about 500-1,000 square metres.

A large central platform will be constructed in Cai Mep Ha Logistics Center where shipments will be transferred into a large-scale cold storage facility. The platform will also include fruit and vegetable processing facilities and an irradiation system to ensure exports meet European and Middle Eastern standards. After processing, fruits and vegetables will be packed in reefer containers and loaded on sea vessels which can surpass a capacity of 20,000 TEU to be exported overseas.

“Ice-Loft is not a fruit trader, we would offer smart cold chain services to the producers to reduce logistics costs and improve the competitiveness of Vietnamese goods in export markets,” Van Bouwel said. “If the first Smart Cold Cabin project proves successful in Tra Vinh, Ice-Loft and our partners will create a master plan for the extrapolation of this technology across the country.”

Once Ice-Loft’s smart cold chain is complete, farmers will be able to dig more into the benefits. Notably, the system will guarantee top quality for buyers through reliable quality control with a system of preservation and monitoring throughout the whole cold chain.

Thus, tropical fruits from Vietnam will gain popularity in the EU and Middle Eastern markets. In addition, this chain will operate on the basis of fair trade with farmers in Vietnam, improving incomes in the community and promoting good partnership among Vietnam and these two markets.

Ice-Loft’s project is part of the Belgian strategy to support the export of innovative high-tech equipment and is a flagship project to the current Belgian-Vietnamese cooperation model.