Microchip ecosystem building up steam

Microchip ecosystem building up steam

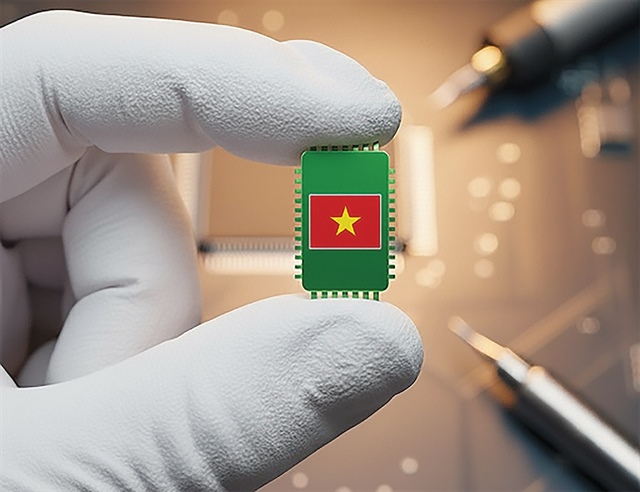

Policy creation for Vietnam’s ambitious semiconductor industry development is being accelerated with the issuance of authority-specific tasks covering infrastructure, personnel, and more.

Vietnam cannot afford to stand by and watch only other nations master the technology |

It is expected that the third meeting of the National Steering Committee on Semiconductor Industry Development will be held by the end of Q3, aiming to speed up development and drive the domestic industrial sector forward.

Prime Minister Pham Minh Chinh, in the second meeting of the committee held last month in Hanoi, underlined that no later than 2027, Vietnam must complete the design, manufacture, and testing of a number of crucial semiconductor chips.

“Efforts are to be made to attract foreign investment in the semiconductor industry, with priority given to projects characterised by advanced, innovative, high-tech, and environmentally friendly technologies, modern management practices, and high added values,” PM Chinh said as cited by a press release from the Government Office. “These projects must have the capacity to generate spill-over effects and connect with global production and supply chains.”

To this end, the country will soon finalise policies to resolve issues in infrastructure, regulatory frameworks, and personnel. Vietnam will also shift the focus of preferential policies from attracting investment to promoting tech transfer, while also developing a competitive, fair, healthy semiconductor market in accordance with market principles.

In addition, the government will foster close coordination between the state, businesses, and educational institutions, ensuring alignment between development planning, research, and production. It also seeks to promote equal development between the public and private sectors, and to build broader public-private and global cooperation mechanisms.

In June, Minister of Finance Nguyen Van Thang reported that in order to attract high-quality foreign funding and develop the private sector, the government will revise investment incentive policies to include binding conditions for tech transfer.

“Large foreign-invested enterprises’ (FIEs) projects are to be required to have plans for the use of domestic supply chains and support small- and medium-sized enterprises (SMEs) in training, testing, and technology sharing from the project approval stage,” he stated.

The issues must be clearly specified with legal requirements to ensure FIEs comply, avoiding the situation of luring foreign investment in simple quantity terms as in the recent past, Minister Thang added.

The government will also review and amend tax policies to incentivise large enterprises to support SMEs. For instance, large enterprises are to be allowed to include in their deductible expenses - as taxable incomes - any costs related to training and retraining human resources for SMEs participating in supply chains.

PM Chinh has also tasked ministries to implement specific jobs to develop the industry in line with the vision to 2050, which aims to position Vietnam as a global hub for chip design, manufacturing, and testing.

The Ministry of Foreign Affairs is requested to enhance bilateral and multilateral cooperation, and mobilise international resources to support human resource development for the industry. It also has to boost Vietnam’s image as a top destination for the industry, and instruct diplomatic missions abroad to advance cooperation and update the database of overseas Vietnamese experts and other talents in the field.

The Ministry of Education and Training will closely oversee training activities under a specific development programme towards 2030, with an orientation to 2050, particularly by strengthening links between the state, academia, and industry to ensure training effectiveness.

The Ministry of Construction, meanwhile, is to propose solutions to ensure transport infrastructure supports the shipping, delivery, and logistics services of semiconductor manufacturing enterprises. It also has to study and issue plans on application of chip technology in transport infrastructure, smart transportation systems, and smart cities.

Meanwhile, the government has asked the Ministry of Agriculture and Environment to propose legal additions regarding strategic minerals for industry development, with focus laid on accelerating mineral surveys to ensure control over input materials, reduce external dependence, and localise relevant supply chains.

The ministry also has to strengthen scientific research and international cooperation to acquire processing tech for these materials, as well as propose licensing mechanisms for the mining and deep processing of strategic mineral resources.

Elsewhere, the Ministry of Justice is to continue working with relevant agencies to improve the institutional, legal, and policy framework to support the rapid development of the semiconductor industry.

“Semiconductors are a key link in the Fourth Industrial Revolution, particularly in the development of AI. It is experiencing rapid growth, with an intense global race to master the technology,” PM Chinh said. “Vietnam cannot afford to stand on the sidelines if it is to build an independent and self-reliant economy, while actively and effectively engaging in deep, substantive international integration.”

Vietnam is making efforts to train at least 50,000 semiconductor engineers by 2030. Currently, the workforce includes around 7,000 engineers working in integrated circuit design companies; and about 6,000 engineers and 10,000 technicians working in packaging, testing, and production of related materials and equipment. The Semiconductor Innovation Network has also brought together over 100 Vietnamese experts from around the world.

Vietnam currently hosts about 170 foreign-invested projects in semiconductors and high technology, registered at around $11.6 billion. This includes major projects from names such as Intel ($4.1 billion), Amkor ($1.6 billion), and Hana Micron ($673 million).

There are now nearly 50 foreign corporations and around a dozen Vietnamese companies including Viettel, FPT, and CMC in the chip design industry; 14 FIEs and one domestic enterprise in packaging and testing; and 15 FIEs in the semiconductor supporting industry.

| Semiconductors are a uniquely global product. Semiconductors are materials, usually silicon, that can conduct electricity and serve essential functions in modern electronic devices to process, store, and transmit data. Semiconductors are often referred as “chips” and play a crucial role in technologies such computing, wireless communication, the internet of things, electronics, and motor vehicles.

The semiconductor industry involves more than 120 different countries (over 60 per cent of the countries in the world) that export or import semiconductor products, and a typical production process involves 3+ trips around the world. Semiconductors constitute the world’s fourth most traded product, with an estimated market value of $520 billion in 2023, and a 10 per cent growth rate in 2024. The process of producing semiconductors is highly complex, involving more than 500 production steps, and can take up to half a year. These steps are commonly grouped into three main activities: l Design: This stage involves setting the requirements of the chip and designing its architecture. It includes extensive research and development to generate the basic knowledge for chip design. The design stage represents about half of semiconductor value added. l Fabrication/foundry: This stage consists in printing the integrated circuit previously designed on a silicon wafer. The process relies on multiple complex and advanced manufacturing stages, including slicing, polishing, and patterning the wafers with integrated circuits using lithography, etching, implanting and other techniques. This stage represents about a quarter of semiconductor value added. l Assembly, testing, and packaging: The individual chips are separated from the wafers, packaged into protective frames, and encased in a resin shell. The chips are rigorously tested for quality and functionality. This stage is less skill- and knowledge-intensive than more upstream activities and represents about 6-10 per cent of semiconductor value added. Once packaged, finished chips are then shipped to electronic devices before being commercialised. The semiconductor industry is highly concentrated geographically, reflecting specialisation and regional networks. The top-5 semiconductor producing economies account for about 75 per cent of semiconductor global value added. Regions specialise in different stages of the semiconductor supply chain based on their comparative advances. While the United States leads in chip designed and advanced manufacturing, East Asia has a comparative edge in wafer fabrication and assembly, packaging, and testing. Source: World Bank |

- 14:55 18/09/2025