CPV promotes 'Made in Vietnam' products at home and globally

CPV promotes 'Made in Vietnam' products at home and globally

C.P. Vietnam (CPV) anticipates that consumers will support 'Made in Vietnam' products that meet international standards, affirming the company's commitment to safety and improving the lives of Vietnamese people. In addition, CPV plans to continue developing new products to meet consumer needs for domestic and foreign markets.

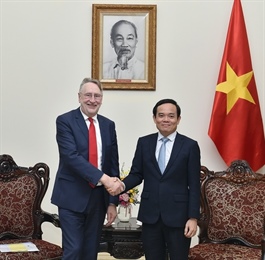

“We have a close partnership with the Vietnamese government and have received substantial support in obtaining export licences. We are currently liaising with agencies to secure export licences for South Korea and the UK, which we anticipate to receive in the third quarter of this year,” said Wirat Wongpornpakdee, senior vice president of New Business and Food Business at CPV.

Halal certification was awarded to CPV Food Binh Phuoc in 2022, meaning CPV is now poised to broaden its exports' horizon to Muslim markets, which comprise approximately 15 per cent of the world’s population. This marks a significant expansion opportunity for the company.

Parent company C.P. Group has implemented the closed 3F model, 'Feed – Farm – Food', in numerous countries, but it views Vietnam as crucial due to the country's significant potential. The company invested a substantial $250 million in the CPV Food factory in Binh Phuoc, which began operation in late 2020. The investment enables the execution of the closed breeding and production model in Vietnam.

Last year was a landmark year for the Binh Phuoc factory, with export volumes tripling compared to 2021 and exports reaching Japan, Hong Kong, Laos, and Cambodia. Binh Phuoc has set ambitious targets for 2024 and beyond. It plans to increase its annual export value to $200 million by penetrating more demanding markets such as Europe, the US, and the Middle East.

CPV Binh Phuoc operates an automatic system that can produce 20,000 tonnes of animal feed per month with a minimal workforce of under 40 individuals. The plant employs advanced technology to ensure the products are of the highest quality.

Moreover, the animal feed is produced from meticulously chosen ingredients and production formulas. The high-quality animal feed is then distributed to farms that raise superior breeds that are continually enhanced and developed. These farms also apply a closed system with a high-tech management structure and a biosecurity system in place to prevent disease. Once the livestock has reached the required age, size, and quality, they are then transported to the food processing factory.

CPV has made significant investments to produce food products that cater to the needs of both the domestic and export markets. “We are extremely proud because we have been able to show the quality of Vietnamese produce to foreign markets. Our partners now carry numerous products labelled, 'Made in Vietnam', Wongpornpakdee said.

In addition to its international exports, Wongpornpakdee explained CPV is focusing on cultivating the domestic market, recognising its immense potential even when compared to export markets.

“Our business plan is centred around enhancing quality standards to earn the trust of Vietnamese consumers. We aim to provide clear and transparent information about our products, processes, and standards. As such, we are investing in technology and human resources to ensure that C.P. is fully integrated into Vietnam,” he said.

After more than 30 years of operating in the Vietnamese market, CPV has observed a significant shift in Vietnamese preferences for consumer foods.

Wongpornpakdee said, “Vietnamese consumers are becoming increasingly more informed about food hygiene and safety through various media and manufacturers, leading them to prioritise quality products that meet hygiene and safety standards. This ensures optimal health for themselves and their families while providing meals that are tasty, safe, and nutritious.”

CPV's 3F closed value chain business model signifies these efforts to enhance the production standards of safe and hygienic foods and reflects the company's understanding of consumer needs, particularly among the younger generation.

“This is the driving force for us to develop more new products,” added Wongpornpakdee.