Mechanical industry turns challenge into driving force for change

Mechanical industry turns challenge into driving force for change

The mechanical industry faces many difficulties due to the Covid-19 pandemic. However, these challenges are also a driving force for change to make manufacturing more efficient and transform supply chains.

Enhancing capacity

According to the Vietnam Association of Mechanical Industry (VAMI), mechanical industry enterprises such as auto makers and assemblers face sharply declining orders but also increased freight costs.

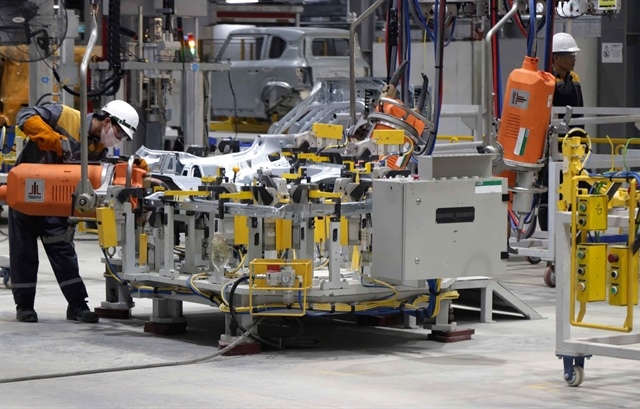

Automobile and parts is an advantageous sub-sector of the mechanical industry

|

Nguyen Van Doan, Deputy Director of SKD Vina Co., Ltd, said export orders face difficulties while transportation costs have increased due to a shortage of freight containers.

Many enterprises in the mechanical industry have changed their business plans and strategies to survive and sustain development. Many have also restructured, changing core processes and using domestic machinery and equipment in production.

Domestic mechanical manufacturing enterprises are proficient in a number of fields such as molds of all kinds, mechanical and plastic components, and electrical cables. In addition, given the high demand for supporting industry products, many businesses have boldly invested to improve production capacity, focusing on developing quality product lines to serve foreign direct investment (FDI) enterprises, and targeting the exports of mechanical products.

VAMI Chair Dao Phan Long said Vietnam also plans to implement many major infrastructure projects in the power sector, a high-speed railway, the Long Thanh international airport; inner-city railway lines; traffic, irrigation, oil and gas works, shipbuilding, and more. “Therefore, the state needs to introduce strict regulations on the reasonable ratio in the volume and value of the project to secure participation of domestic mechanical enterprises, which will help improve their capacity and connectivity,” said Long.

Focus on three sub-sectors

According to the Ministry of Industry and Trade, in order to overcome this difficult period, Vietnam's mechanical industry needs to identify market demand and shortages in order to develop areas in which they have competitive advantages. In addition, mechanisms and policies must be flexible to encourage enterprises to invest and expand production.

Many businesses have boldly invested to improve production capacity

|

Vietnam’s commitments under many free trade agreements (FTAs) will provide domestic enterprises with more advantages when exporting to other markets, and attracting foreign investment into Vietnam. In order to take advantage of opportunities, enterprises need to develop detailed linkage plans in the production and supply of equipment and machinery manufactured by Vietnamese enterprises themselves, form clusters of enterprises to expand production and meet new requirements.

According to the Vietnam Industry Agency under the MoIT, Vietnam's mechanical industry now has advantages in three sub-sectors: motorcycles and motorcycle spare parts; household mechanics and tools; automobiles and parts. They are mainly export-oriented or supply FDI enterprises, accounting for nearly 70 percent of the country’s total mechanical industry production value.

The MoIT will continue to develop a number of downstream industries, including energy industry, precision engineering to secure the development of the mechanical industry.

| Vietnam’s participation in a series of FTAs and the dramatic shift in global investment flows will provide great development opportunities for Vietnamese mechanical enterprises. |