La Vie – flagship in accelerating circular economy

La Vie – flagship in accelerating circular economy

La Vie, a member of Nestlé Group, has become the first brand to remove unnecessary, litter-prone tamper-evident plastic seals in Vietnam. The company has just launched the La Vie 700 ml bottled in food-grade recycled plastic in Vietnam. Bich Ngoc talked with CEO Fausto Tazzi about La Vie’s sustainable development strategy and how the company has achieved its targets on schedule.

Fausto Tazzi, CEO of La Vie shared the company's sustainable development strategy in Vietnam. Photo: Le Toan

|

La Vie is the first company in Vietnam pioneering with a range of activities to recycle plastic bottles toward a circular economy. What have you done to achieve this target?

La Vie is the first brand to remove unnecessary litter-prone tamper-evident plastics in Vietnam.

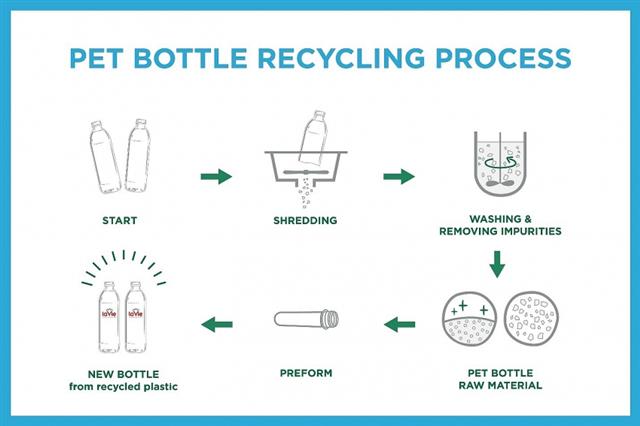

Before the launch of La Vie 700ml – 50 per cent rPET bottle that is the first mineral water product bottled in food-grade recycled plastic in Vietnam, we have done many activities, including the removal of plastic cap seal starting with La Vie 350 ml bottles from 2018 which we then expanded to other bottle sizes.

We are also a founding member of the Packaging Recycling Organisation Vietnam (PRO Vietnam) which consists of many other international companies which are also operating in Vietnam. At PRO Vietnam, we are promoting the collecting and recycling progress.

We are aware that we cannot resolve the plastic problem alone because even if La Vie collects and recycles all of its products, it only occupies 1 per cent of the total market for all types of water. Therefore, we need to cooperate with other manufacturers and so PRO Vietnam was born. Together with non-members, PRO Vietnam is doing great efforts to collect used bottles and recycle them.

By 2025, your objective is to have 100 per cent of your packaging recyclable or re-used by 2025. How can you achieve this target on schedule?

In our vision for a waste-free future, we are focusing on three fields: developing sustainable packaging, shaping a zero-waste future, and driving new behaviours and understanding.

The initiative to use rPET packaging not only contributes to reducing the use of virgin plastic but also provides the opportunity to regenerate each bottle collected, motivating collection and recycling projects in Vietnam.

This will also promote a circular economy for plastics bottles and turn waste into resources instead of being discharged into the environment, step by step helping consumers formulate a new mindset on solutions to the current waste problem.

Our target is to be plastic neutral by 2025, which means we will collect the amount of plastic equivalent to what we generate from our packaging. Plastic which is of the requisite quality would be recycled into food-grade recycled plastics while lower-quality waste would be used to produce other things such as t-shirts and suitcases.

Plastics which are of the requisite quality would be recycled into food-grade recycled plastics. Photo: Le Toan.

|

Currently, beverage companies face many challenges in using recycled plastic because there are no enterprises producing food-grade recycled plastics. How are you planning on working with local manufacturers to deal with this?

As we are based in Vietnam, it is not good to get a supply of recycled bottles from abroad. It would be far more feasible if local companies could supply us. When local recycled bottle manufacturers are available, we can work together on solutions not only for recycling but for the sorting of used bottles from the beginning to keep the used bottles in the best shape to be recycled as food-grade containers.

Today, some Vietnamese producers are aware of plastic recycling and are making further studies to manufacture recycled food-grade containers. There are also some Taiwanese and European companies expressing interest in producing food-grade rPET in Vietnam.

The challenges for manufacturing rPET in Vietnam are various. The key point to have food-grade rPET is to keep the used containers as clean as possible when they are collected.

In order to achieve this, we need to classify waste as soon as possible right after use because if the used bottles are polluted by other things, they cannot be used to produce food-grade plastics, although they can be turned into other things that are non-food grade.

The recycled plastic bottles are not only sustainable but have very nice performance as well. Photo: Le Toan

|

What message would you like to convey to Vietnamese customers via your initiatives?

Through these initiatives, La Vie is trying to point out the huge demand for food-grade recycled plastics from beverage companies like us, thereby encouraging domestic enterprises to invest in rPET production to further accelerate the circular economy.

We want to send a message to manufacturers that we will for sure consume rPET if they are made in Vietnam.

Nowadays, people do not like plastics, however, plastics themselves are not bad – the problem lies in inappropriate treatment after use. Recycled plastic bottles can not only be sustainable but perform very nicely.

What is your approach to the circular economy?

The circular economy is a new concept not only in Vietnam but also in the world. It has become a serious global issue a couple of years ago. There are now few initiatives on the circular economy but the model will gather strength very soon.

I have been in talks with many organisations such as the World Bank and some capital funds. All of them are ready to finance circular economy projects in Vietnam. The point is that there are not many projects right now. The beginning initiatives would be very small, but little by little we will come up with bigger initiatives.

La Vie’s role is to kickstart all this. Plastic recycling is feasible and we will make it larger together.

To have a circular economy, it is not only important to find somebody who wants to use recycled PET bottles in Vietnam but also to give this person or enterprise the guidance to keep plastic waste at a high enough quality to be recycled.