Action needed to reduce pollution from printing industry

Action needed to reduce pollution from printing industry

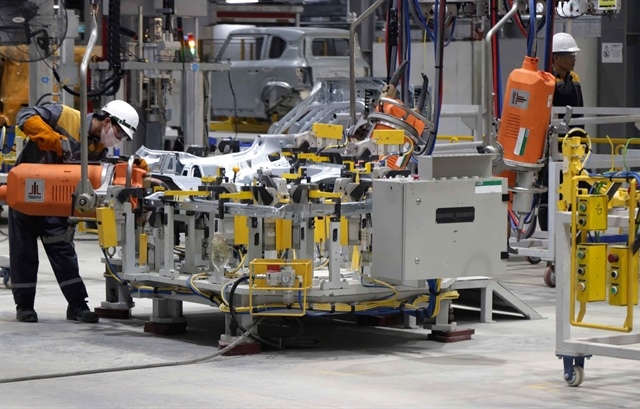

Enterprises in the printing industry have discussed solutions, including a switch to plant-based, ecofriendly input materials, to reduce environmental pollution created by parts of the printing process.

The stages that exert a negative impact on the environment include gas emissions; the handling and disposal of hazardous materials and waste; and the management and use of energy, said Dr. Nguyen Long Giang from the Faculty of Graphic Arts and Media, under the HCMC University of Technical Education, at a conference in HCMC on September 19.

As for gas emissions that cause air pollution, Giang said that printing plants release Volatile Organic Compounds into the atmosphere when manufacturing solvents. These compounds easily turn into vapors or gases.

Hazardous waste such as solvent waste and photographic chemical waste from the printing process is one of the causes of global warming. Also, these chemical and solvent substances pose a high risk to the environment when they contaminate plants, water resources and farmland and harm agricultural products.

Giang suggested printing operators use paper and other raw materials from suppliers who meet requirements for environmental protection. For instance, reusable paper is recommended as it generates less carbon dioxide than other materials that are environmentally substandard.

Besides this, operators in the industry are advised to replace oil-based inks with plant-based ones. This could help reduce harm to the environment, he added.

Printing operators also need to upgrade their operating systems with advanced technology, such as Total Quality Management solutions, which are energy-efficient, save time and significantly reduce waste.

Meanwhile, Tony Tan, a technical expert with German firm Bottche, said that the entire operating system from printing materials and printers to printing staff should be replaced to cushion the adverse environmental effects created by the local printing industry.

Commenting on the benefits of environmentally friendly printing materials, Nguyen Quoc Khoa, a representative of Toan An Company, pointed out that many leading global technology suppliers have managed to eliminate or minimize the use of chemicals in the printing process.

According to a study by Kodak, the use of ecofriendly printing pallets in recent years has annually saved over 360 liters of water, 139 million kilowatt hours of electricity and more than 2.7 million liters of chemicals.